Hillside Machine's In shop and "On Site" boring technicians have built up an extensive range of experience cylinder boring and honing utilizing precision portable machining and stationary equipment. A range from small to large diameter bore application. Our Infield cylinder boring and honing machining team, comprising of highly skilled technicians all with many years experience in mechanical equipment repairs will succeed where many others have failed. Hillside Machine main focus is to provide accurate clinder boring and cylinder honing machining facilities on site reducing equipment downtime, and increasing productivity.

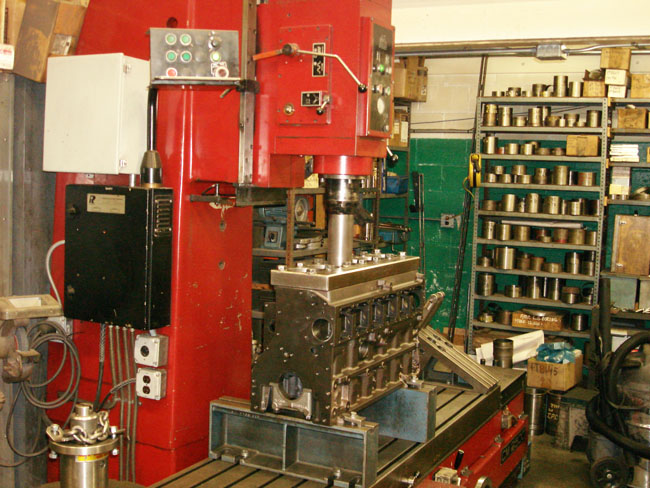

Hillside Machine utlizes the AMC 2500V Bore Mill for in shop boring and sleeving. Our equipment also includes Kwik Way and Van Norman portable boring bars for our Infield boring operations.V-8 Automotive Blocks are Bored on our Rottler F2V

Boring Spindles

A complete range of spindles allows boring from 32-350 mm (1.25"-13.75"). All spindles feature constant pre-loaded bearings and are sealed and greased for life.

Lower Bore Repair

Infield Boring Bars-Insitu Boring Service

Boring Spindle 1-4

AMC-SCHOU supplies a full range of spindles. Above are spindles covering the range from 48-260 mm (1.89"-10.24")

No. 1: 48-72 mm (1.89"-2.83")

No. 2: 62-100 mm (2.44"-3.94")

No. 3: 92-200 mm (3.62"-7.87")

No. 4: 145-260 mm (5.71"-10.24")

Phone:1-781-321-9625

Torque Plate Honing

Cylinder Boring and Torque Plate Honing

Torque Plate Boring Cat C-7 Block

Torque Plate Horing Cat C-7 Block